Course overview

Loading...

Course content

Loading...

Learning objectives

Loading...

Loading...

Loading...

Loading...

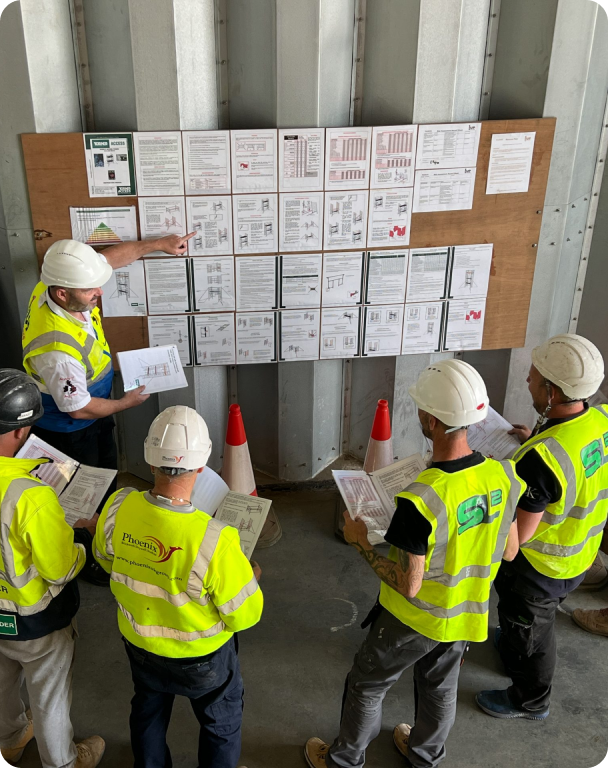

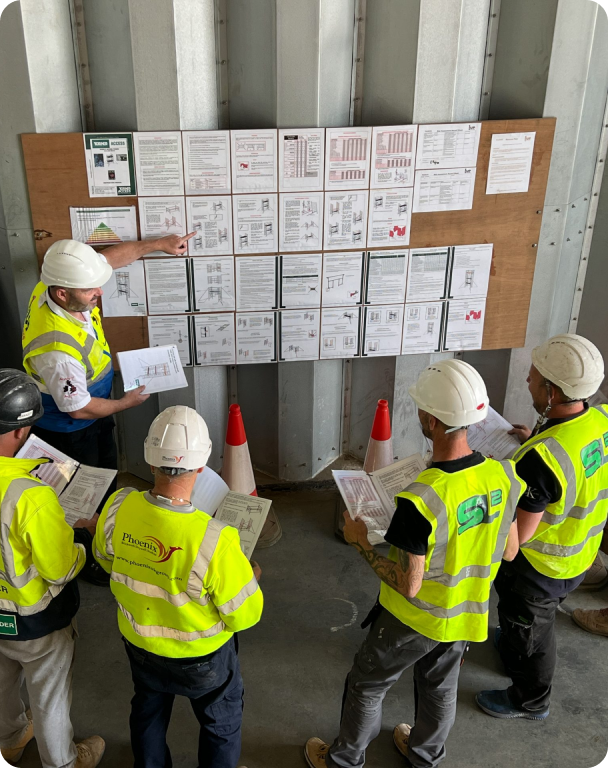

Training4industry are one of the leading industry training providers in the north of England.

We pride ourselves in training people to the highest possible standards with safety being at the forefront of our business.

We are fully accredited with the necessary awards and have high standards for our organisation and our staff.

We are a recognised training provider within the UK construction industry and have been awarded by national bodies such as IPAF, PASMA, Qualsafe and CITB Site Safety Plus. We provide a competitive pricing structure and we achieve this by employing our own instructors and using our own training facilities which are of a very high standard. Our training facilities are among the best in the UK, trust us to keep your staff safe.

26k+

Students

60+

Active Courses

12k

Customers

Our Instructors have over 40 years’ experience in all aspects of Health & Safety training and our training facilities are among the best in the UK. We are one of the UK`s leading independent training providers for IPAF and PASMA courses and we offer a huge selection of Health & Safety training courses such as the SMSTS Site Management, SSSTS Site Supervisor, Confined space, First Aid, CPC and many more courses are available.

Training4industry are one of the leading industry training providers in the north of England.

We pride ourselves in training people to the highest possible standards with safety being at the forefront of our business.

We are fully accredited with the necessary awards and have high standards for our organisation and our staff.

We are a recognised training provider within the UK construction industry and have been awarded by national bodies such as IPAF, PASMA, Qualsafe and CITB Site Safety Plus. We provide a competitive pricing structure and we achieve this by employing our own instructors and using our own training facilities which are of a very high standard. Our training facilities are among the best in the UK, trust us to keep your staff safe.

26k+

Students

60+

Active Courses

12k

Customers

Our Instructors have over 40 years’ experience in all aspects of Health & Safety training and our training facilities are among the best in the UK. We are one of the UK`s leading independent training providers for IPAF and PASMA courses and we offer a huge selection of Health & Safety training courses such as the SMSTS Site Management, SSSTS Site Supervisor, Confined space, First Aid, CPC and many more courses are available.

As the assembly and use of MEWPs can be physically demanding, users should be physically fit and in good health and should, generally, not have problems with eyesight or hearing, heart disease, high blood pressure, epilepsy, fear of heights/vertigo, giddiness/difficulty with balance, impaired limb function, alcohol or drug dependence or psychiatric illness.

If you have any problems with literacy or language comprehension, or have any doubts about your fitness to use MEWPs, you must bring them to the attention of your employer. This need not preclude you from using MEWPs, provided your employer conducts an assessment and is able to put into place adequate measures, to take account of any difficulties you may have.

All applicants must have satisfactorily completed a recognised Operator’s course.

They should hold a valid Operator’s licence for the relevant categories of plant e.g. MEWP, Forklift, Dumper OR the Employer must provide written evidence of competency of plant operation before commencing the course.

Applicants should also hold a current driving licence for the type of vehicle to be loaded or the Employer must provide written evidence of the candidate’s familiarisation with the vehicle.

INTRODUCTION

Facilities, Objectives, Health and Fitness Statement.

REGULATIONS

HSWA 1974 – Employer’s and employee’s responsibilities. Road Traffic Act – Dangerous Driving including overweight and unsecured loads, consequences e.g. fines and imprisonment. Management Regs 1999 – Risk Assessment PUWER 1998 – Adequate training for purpose of Health & Safety on machinery to be used. LOLER 1998 – Ancillary lifting equipment including Suitability, Maintenance, Inspection and Records. Road Vehicles (Construction and Use) Regulations 1986 – reference to unsecured loads. Department for Transport – Approved Code of Practice for Safety of Loads on Vehicles.

VEHICLE TYPES

Small vehicle and Trailer < 3.5 t. Flatbed up to 7.5 t. LGV 2 axle rigid 18 t. LGV 3 axle rigid 26 t. LGV 4 axle rigid 32 t. Tractor unit and articulated trailer.

VEHICLE LOAD

RISK ASSESSMENT

Generic, Specific and Visual. Definition of a Hazard. Definition of a Risk. Calculation of Risk potential. Action to take when risks identified. Every time we load/unload make a mental note, continually monitor by observation. Identify potential hazards and means of reducing or eliminating the risk.

LOADING

Load central – not to one side of body, axle weights not compromised, not wedged against other part of load. Avoid against headboard or tailboard. How to calculate load on front axle.

SECURING

Chains & fasteners, straps & tensioners, different type hooks and retaining clips, double reeving block and wheel chocks. Restraining strength 100% of load forward, 50% sideways backwards. Amount of equipment carried – adequate and inspected at suitable intervals – daily.

Use of correct tie-down points on the vehicle and load. Possibility of side forces. Two chains/straps pulling opposite directions minimum. Strap/chain angle less than 60 degrees to maximise load security. Fasteners down same side away from traffic. Work from ground wherever possible.

UNLOADING

Risk assessment re: overhead cables/ obstructions, ground conditions, type of machines, proximity of place where machine to be left. If using winch on slope have cab uphill. Traffic and other persons, weather and light. Lowering of ramps and run off clearance. Ramp spacing and width of machine to unload.

Method of unloading: Drive it off unassisted. Use of winch – when, why, how, possible shock loading. Use of Hiab or Forklift (operator must be trained also refer to LOLER regs). Order of unfastening when on slope – lower fasteners first. Avoid trip hazard with chains – good housekeeping. Never stand between unsecured machines. Work from ground wherever possible to reduce risk of trips/falls on vehicle body. Determine direction of travel before moving machine.

Leaving machine when off loaded: Safe position, power source isolated, secured, key removed.

SUMMARY

THEORY TEST

Multiple-choice questions answered individually with aid of course notes.

PRACTICAL

Practical Session to include:

At the end of the course the candidate will:

THEORY

The candidate should know: